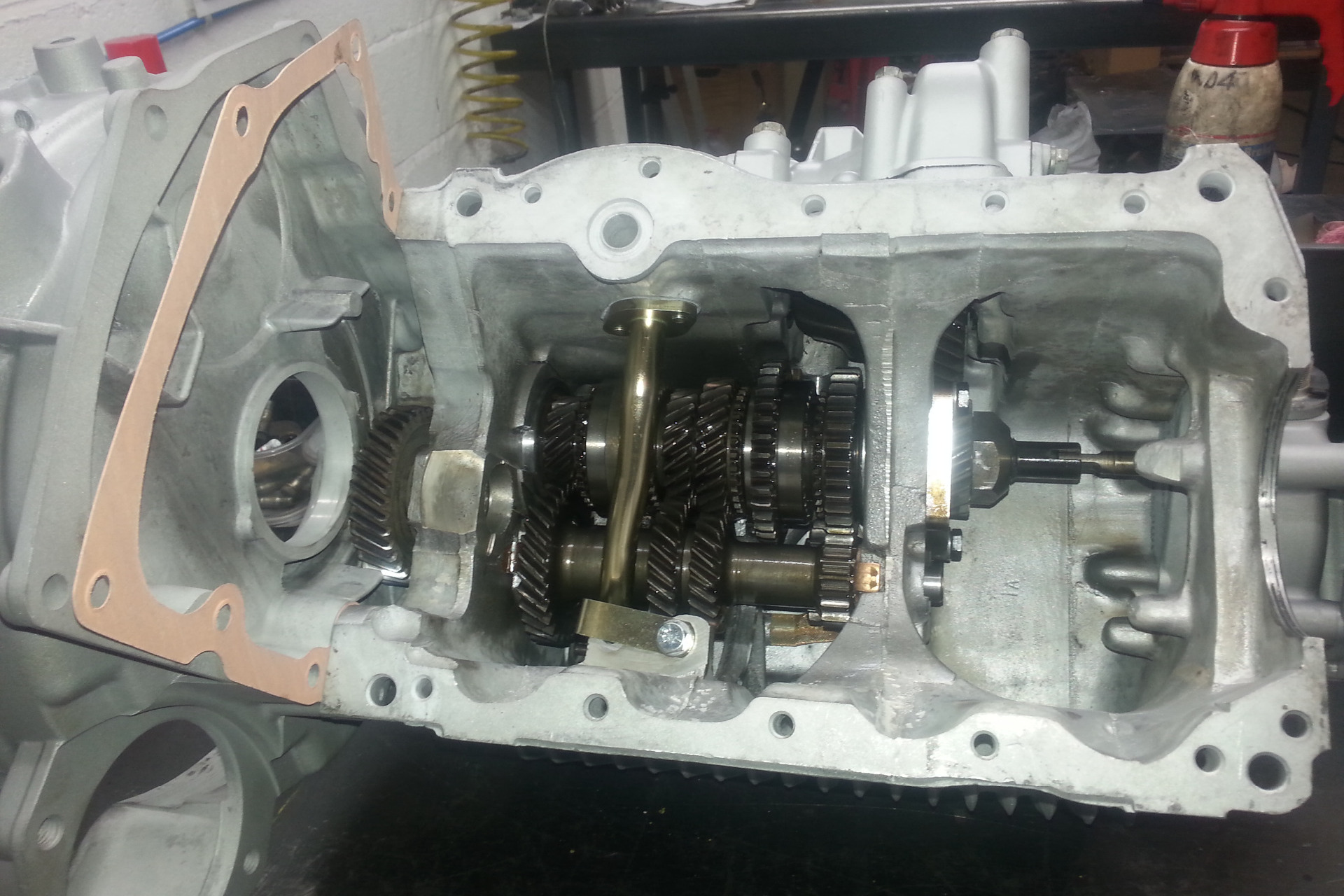

GEARBOX

With all the effort put in to optimising engine output, getting in to building and re-building gearboxes was an obvious requirement. When I started racing it seemed there were precious few who knew how to do that, and those that did were not at all forthcoming with information. Not at all daunted by gearboxes, having built loads of different motorcycle 'boxes prior to my Mini endeavours, I just got stuck in with the good old workshop manual.

Having discovered how the internal workings operated, and getting a grip on what was needed to refine them and to make them work more efficiently, I started a long career of re-building gearboxes for the multitudes. Many folks were keen as mustard to have a crack at an engine build, but gearboxes? Spawn of the devil to them. Good for me in many ways. It furthered my knowledge and experience no end, and contributed handsomely to my racing!

Standard helical, straight cut and dog boxes are all easy meat to me. Whether they use standard final drive and diff units or limited slip diffs with associated specific final drive, no problem. Just a refresh of a standard road unit, or full on from new race 'box build.

I have even developed a dog box gear kit for the in-line A-series racers. One that fits, is super reliable, and makes use of previously discard and now getting rare rib case casings. Typically these casings are discarded because the layshaft bore hole at the 1st gear end wears oval and goes baggy. This causes all kinds of mayhem, including broken gear teeth and trashed laygears. Even split/cracked casings. My design solves that problem and removes the layshaft flexing issue of the standard shafts.

- PRODUCTS AND SERVICES -